A couple years ago when the eMR2 was still in the design stage, there were two competing coupler designs: a simple dual spline coupler (described in a previous post here) and a more complex design that incorporated the spring cushion hub from a stock MR2 clutch.

Incorporating the cushioned hub would insulate the splines for shock loads and provide a little misalignment tolerance. After the experience with the straight coupler these durability advantages, along with a provision to securely clamp the coupler to the shaft to prevent any axial movement, made the additional cost of the design justifiable.

The clutch hub was harvested from an ACT performance street clutch disc and cost about $90.

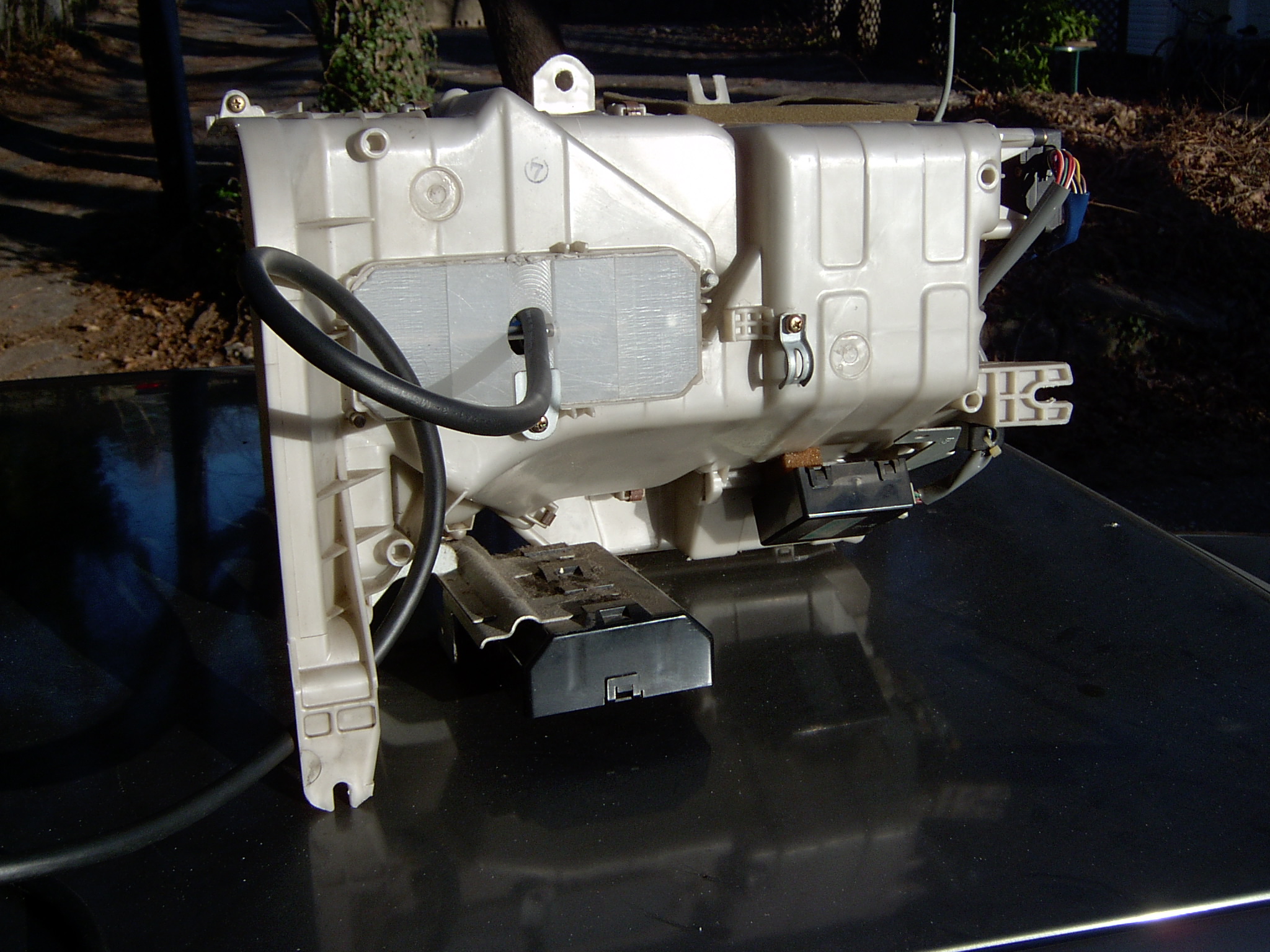

The rivets fastening the friction disk to the hub were carefully drilled out. The rivets also serve as spacers for the hub plates and can be seen at the bottom of this picture:

Substitute spacers with the proper ID to fit the 1/4″-28 screws that replaced the rivets were easily sourced from McMaster-Carr. They can be seen between the screw and old spacer.

The yoke was machined by Robert at Artistic Machining and then sent to Form Tools to have the spline EDM’ed. A shaft collar was also incorporated into the design to nail the whole thing down.

All the parts were put together with red Loktite and installed just prior to bolting together the motor and transmission.